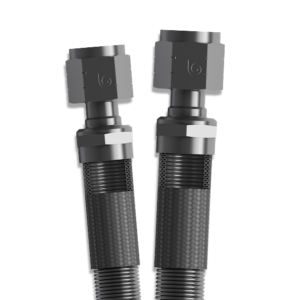

Description

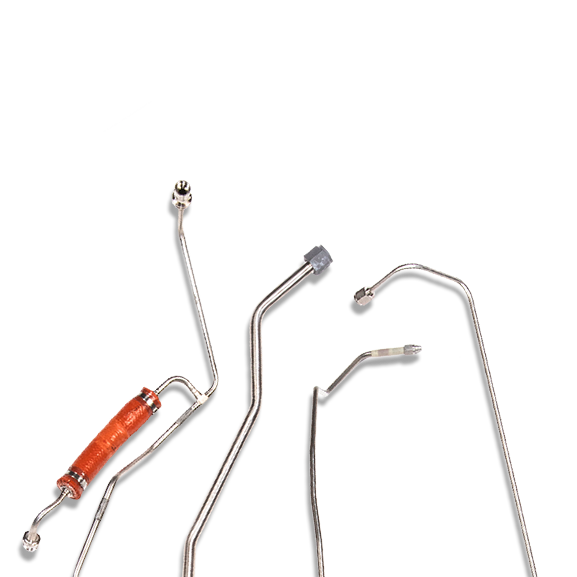

Aero-Hose, Corp. partners with Titeflex Aerospace to offer a wide range of in-house rigid tube assembly fabrication capabilities to service the demanding applications and requirements of the aerospace industry.

With a deeply skilled and knowledgeable team, Titeflex Aerospace is accustomed to working with all aerospace material types, including but not limited to, Austenitic and “PH” Stainless Steels, Nickel Alloys (600, 625, 718, X750, Waspaloy, and Hastelloy), Titanium, and Aluminum.

Tube forming capabilities include rotary draw tube bending to 3" diameter, roll sweep bending to ¾" diameter, coiling to ½" diameter, end finishing, and press forming. Formed assemblies can be completed with several fitting types to include single flare, double flare, welded, and internal and external swaging. Metal joining capabilities include orbital and manual GTAW (Gas Tungsten Arc Welding), induction brazing, vacuum furnace brazing, and torch brazing. Titeflex Aerospace also performs vacuum heat treating (stress relieving, solution heat treating, and precipitation hardening) of materials other than Aluminum.

As companions to metal joining, Titeflex Aerospace has a non-destructive testing lab certified for radiography and liquid penetrant inspection and in-house cleaning capability including titanium cleaning. Non-destructive testing capabilities also include pressure testing with media and pressures as follows:

- Air / Nitrogen / Helium 8,000 PSI

- Water 15,000 PSI

- Skydrol 8,000 PSI

In addition to routine cleaning, Titeflex Aerospace also performs special cleaning, testing [particle count and NVR (Non-Volatile Residue)], and protective packaging of components for oxygen systems and other systems having special cleanliness requirements.

Titeflex Aerospace holds numerous aerospace customer approvals for special processes and are Nadcap accredited in Welding & Brazing, Furnace Brazing and Heat Treatment, Chemical Processing (including Titanium cleaning as well as Non-Destructive Testing [Radiography and LPI (Liquid Penetrant Inspection)].