Quality Hose Assemblies for Commercial Aircraft

In the demanding world of commercial aviation, selecting the right hose and tube assembly partner is critical. For large commercial jet applications, quality, service, and performance are non-negotiable—they are a baseline requirement. Aero-Hose, Corp., founded in 2004, has established a legacy of delivering engineering-driven solutions with unparalleled efficiency, offering lead times far shorter than the industry standard while maintaining uncompromising quality and performance.

Proven Expertise for Complex Applications

Aero-Hose, Corp. brings an aerospace pedigree that ensures every product meets rigorous testing and quality verification standards. From traditional fuel, hydraulic, and pneumatic lines to intricate hose and tube combinations, their assemblies are found in aircraft systems spanning nose to tail. This extensive range demonstrates the company's adaptability and commitment to addressing the diverse needs of commercial aviation.

With Aero-Hose, Corp., airlines and manufacturers gain access to:

- Pressure-Resistant Hoses: Engineered for reliability across a range of operating pressures.

- Customizable Fittings: Offered in multiple materials and configurations to meet specific aircraft requirements.

- Specialized Sleeving Options: Designed to endure extreme heat and high-chafe environments, providing long-lasting durability in harsh operating conditions.

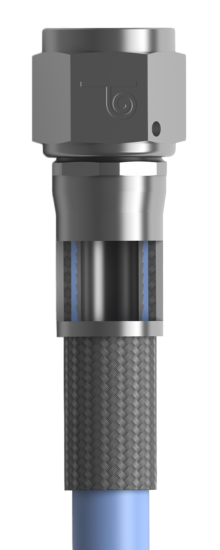

Spotlight on the 240 Series Aerospace Hose

The 240 Series high-pressure aerospace hose is a lightweight solution built for performance and reliability, qualified to AS1339 standards.

- Construction and Materials:

- Inner Core: Conductive, extruded smoothbore PTFE with superior chemical resistance.

- Reinforcement: CRES 304 wire braid, with single-layer reinforcement for smaller sizes (-04 through -10) and double-layer reinforcement for larger sizes (-12 through -24).

- Temperature Range: Reliable operation between -65°F to +400°F (-54°C to +204°C) with unlimited shelf life.

- Bend Radius: Industry-leading flexibility, thanks to pre-tensioned braid construction.

- Fitting Options and Material Versatility:

- Standard fittings are CRES, with lightweight titanium available for applications requiring weight reduction.

- Fire Protection and Sleeving:

- Fire resistance compliant with AS1055 Class A & B through integral or slip-on AS1072 firesleeve.

- Chafe sleeves offered in a range of integral or slip-on materials for added protection.

Hybrid Assemblies for Enhanced Performance

Aero-Hose, Corp.’s hybrid assemblies, combining flexible hose with multi-bend tube, are engineered for superior vibration dampening, easier installation, and reduced maintenance needs. These assemblies, available in sizes -16 to -24, are optimized for critical applications where rigid tube solutions are less effective.

Why Choose Aero-Hose, Corp.?

For commercial aviation leaders, Aero-Hose, Corp. provides not just products, but comprehensive solutions designed to meet the unique challenges of large commercial jet applications. Their unmatched ability to innovate, customize, and deliver under tight timelines makes them the trusted partner for reliable hose and tube assemblies. With Aero-Hose, Corp., you can count on quality, service, and performance every step of the way.

Featured Product

Series

240

Specification

SAE AS1339

Braid

CRES

Innercore

PTFE Smoothbore

Qualification

SAE AS1339

TSO C75 Type IIIB-S/P-F

AS1055 Type IIa & IIb, Class A & B,

Integral and Slip-on Firesleeve

Full Catalog

Aero-Hose, Corp. offers a broad range of products for Commercial applications.