Hose Assemblies for Military Aircraft Applications

When selecting a partner for hose and tube assemblies in military aircraft applications, the priorities are clear: quality, service, and performance. Aero-Hose, Corp., with its extensive aerospace pedigree, stands out as a leader in this critical field.

Unmatched Expertise and Proven Reliability

With decades of experience and the successful manufacture of hundreds of thousands of assemblies, Aero-Hose, Corp. is the trusted choice for military aviation. Every product undergoes rigorous testing and quality verification processes to meet the highest aerospace standards. Whether it's standard fuel and hydraulic lines or complex hose/tube combinations, Aero-Hose, Corp.'s assemblies are relied upon by military aircraft worldwide.

Aircraft used for combat, troop transport, aerial refueling, or other mission-critical applications benefit from Aero-Hose, Corp.'s commitment to excellence. With the company, quality, service, and performance are guaranteed.

Comprehensive Product Offerings

Aero-Hose, Corp. delivers an extensive range of products designed to meet diverse military aviation needs:

- Customizable Hose Options: Capable of withstanding any pressure requirement, these hoses are designed with precision.

- Variety of End Fittings: Available in multiple materials and configurations to ensure compatibility and durability.

- Specialized Sleeving Options: Designed for extreme heat or high-chafe installations, these sleeves provide optimal protection in demanding conditions.

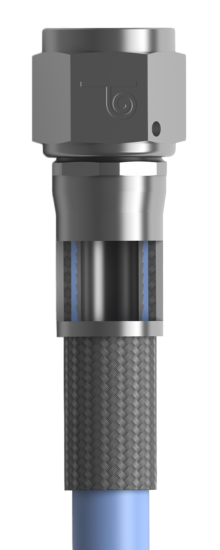

Spotlight on the 240 Series Aerospace Hose

The 240 Series lightweight high-pressure aerospace hose, qualified to AS1339, exemplifies Aero-Hose, Corp.’s dedication to performance and reliability.

- Design and Construction:

- Inner Core: Extruded smoothbore PTFE, offering excellent chemical resistance and conductivity.

- Reinforcement: CRES 304 wire braid with a single layer for sizes -04 through -10 and a double layer for sizes -12 through -24.

- Temperature Range: Operates effectively from -65°F to +400°F (-54°C to +204°C) with an unlimited shelf life.

- Bend Radius: Tightest bend radius among metal braided high-pressure PTFE hoses, thanks to pre-tensioned braid.

- Fittings and Material Options:

- Standard material is CRES, with titanium options available for weight savings.

- Fire Protection and Sleeving:

- Fire resistance per AS1055 Class A & B can be achieved with integral or slip-on AS1072 firesleeve.

- Chafe sleeves are offered in various integral or slip-on materials for added durability.

Hybrid Assemblies: Advanced Performance

Aero-Hose, Corp. specializes in hybrid assemblies that combine flexible hose with multi-bend tube. These assemblies provide superior vibration dampening, easier installation, and simplified maintenance compared to rigid tube solutions. Available in sizes -16 to -24, these hybrids exceed traditional performance expectations and are particularly suited for high-demand applications.

Trust Aero-Hose, Corp. for Mission-Critical Applications

From fuel systems to hydraulic lines, Aero-Hose, Corp. delivers reliable and innovative solutions for the aerospace and defense sectors. With unparalleled quality assurance and an unmatched product range, Aero-Hose, Corp. ensures mission readiness for military aircraft worldwide.

Featured Product

Series

240

Specification

SAE AS1339

Braid

CRES

Innercore

PTFE Smoothbore

Qualification

SAE AS1339

TSO C75 Type IIIB-S/P-F

AS1055 Type IIa & IIb, Class A & B,

Integral and Slip-on Firesleeve

Full Catalog

Aero-Hose, Corp. offers a broad range of products for Commercial applications.