High-Quality Hose Assemblies for Rotary Wing Aircraft

In rotary wing aircraft, reliable performance, safety, and weight reduction are critical factors. From military helicopters to commercial rotorcraft, Aero-Hose, Corp. delivers quality aerospace hose assemblies engineered to meet these demanding requirements without compromise.

Lightweight Solutions Without Compromising Safety

Aero-Hose, Corp. leverages advanced materials and design innovations to provide lightweight solutions that maintain top-tier safety and performance. By utilizing materials such as aluminum end fittings and composite braid reinforcements, Aero-Hose, Corp.’s products reduce weight while enhancing reliability. These assemblies undergo rigorous testing and quality verification to ensure compliance with aerospace standards, making them ideal for rotary wing fuel, hydraulic, and pneumatic systems.

With decades of experience and hundreds of thousands of assemblies manufactured, Aero-Hose, Corp. has established itself as the go-to partner for critical rotary wing applications, supporting operations worldwide.

Comprehensive Aerospace Hose Assembly Offerings

Aero-Hose, Corp.’s extensive product line for rotary wing aircraft includes:

- Lightweight Materials: Aluminum and composite braid options designed for weight-sensitive aircraft systems.

- Customizable Fittings: Available in a range of configurations to meet diverse system requirements.

- Certified Safety Solutions: Fully certified assemblies for fuel, hydraulic, and pneumatic systems.

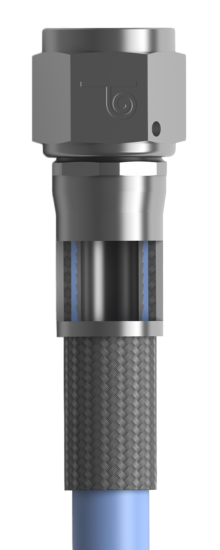

Spotlight on the 240 Series Aerospace Hose

The 240 Series high-pressure aerospace hose, qualified to AS1339, exemplifies Aero-Hose, Corp.’s commitment to quality and innovation.

- Design and Materials:

- Inner Core: Conductive, extruded smoothbore PTFE for excellent chemical resistance.

- Reinforcement: CRES 304 wire braid, with a single layer for sizes -04 through -10 and a double layer for sizes -12 through -24.

- Temperature Range: Operates reliably between -65°F to +400°F (-54°C to +204°C) with unlimited shelf life.

- Performance Features:

- Provides the tightest bend radius of any metal-braided high-pressure PTFE hose, thanks to pre-tensioned braid construction.

- Rated for 3000 PSI (207 Bar), ensuring dependable performance in high-pressure environments.

- Material and Protection Options:

- Fittings: Standard CRES fittings with optional titanium for additional weight savings.

- Fire Protection: Compliant with AS1055 Class A & B, using integral or slip-on AS1072 firesleeve.

- Chafe Sleeves: Available in integral or slip-on designs to prevent wear in harsh conditions.

Advanced Hybrid Assemblies

Aero-Hose, Corp.’s hybrid assemblies, which combine flexible hose with multi-bend tubing, provide enhanced vibration dampening, simplified installation, and reduced maintenance. Available in sizes -16 to -24, these hybrids are optimized for the unique demands of rotary wing aircraft systems.

Why Choose Aero-Hose, Corp. for Rotary Wing Applications?

With decades of expertise, innovative lightweight solutions, and a commitment to excellence, Aero-Hose, Corp. is the trusted partner for rotary wing aircraft hose assemblies. By delivering quality aerospace hoses tailored to critical applications, Aero-Hose, Corp. ensures that safety, performance, and weight efficiency are never in question. For fuel, hydraulic, and pneumatic systems, Aero-Hose, Corp. provides the reliability and innovation rotary wing aircraft demand.

Featured Product

Series

240

Specification

SAE AS1339

Braid

CRES

Innercore

PTFE Smoothbore

Qualification

SAE AS1339

TSO C75 Type IIIB-S/P-F

AS1055 Type IIa & IIb, Class A & B,

Integral and Slip-on Firesleeve

Full Catalog

Aero-Hose, Corp. offers a broad range of products for Commercial applications.